Parts Search

We have access to a trusted, extensive global sourcing network. Select below whether you would like to search for a single part or multiple parts in one go. Enter the part number for your required electronic component in the box below and click 'search'.

Fast Part Search

Electronic component obsolescence management

9 October 2023

Whether you need to source or dispose of parts, electronic components are becoming obsolete faster than ever before.

What is part obsolescence?

Part obsolescence is a term used in the manufacturing and technology industries to describe a component or product which is no longer available from the original manufacturer in the original specification. It might be unavailable due to the manufacturer's closure or discontinuation of that specific part due to inefficiency, lack of durability or functionality. The demand for a component may dry up because the products it is designed into are becoming unpopular or obsolete themselves. One of the main causes of obsolescence is the mergers and acquisitions of component manufacturers, which have an inevitable impact on the longevity of supply chains and the availability of various components.

Electronic component obsolescence can be triggered by:

- Shortage of essential raw materials

- Emerging regulations concerning substances

- Extended lead times

- Mergers and consolidations

- Additional disturbances (natural calamities, pandemics, etc.)

As a result, it can be very hard to predict component obsolescence and it remains an inherent challenge for OEMs as they strive to align supply with demand. Ignored, parts obsolescence drives up development, production, and maintenance costs, along with potential redesign and conformity costs.

Why is part obsolescence a growing problem?

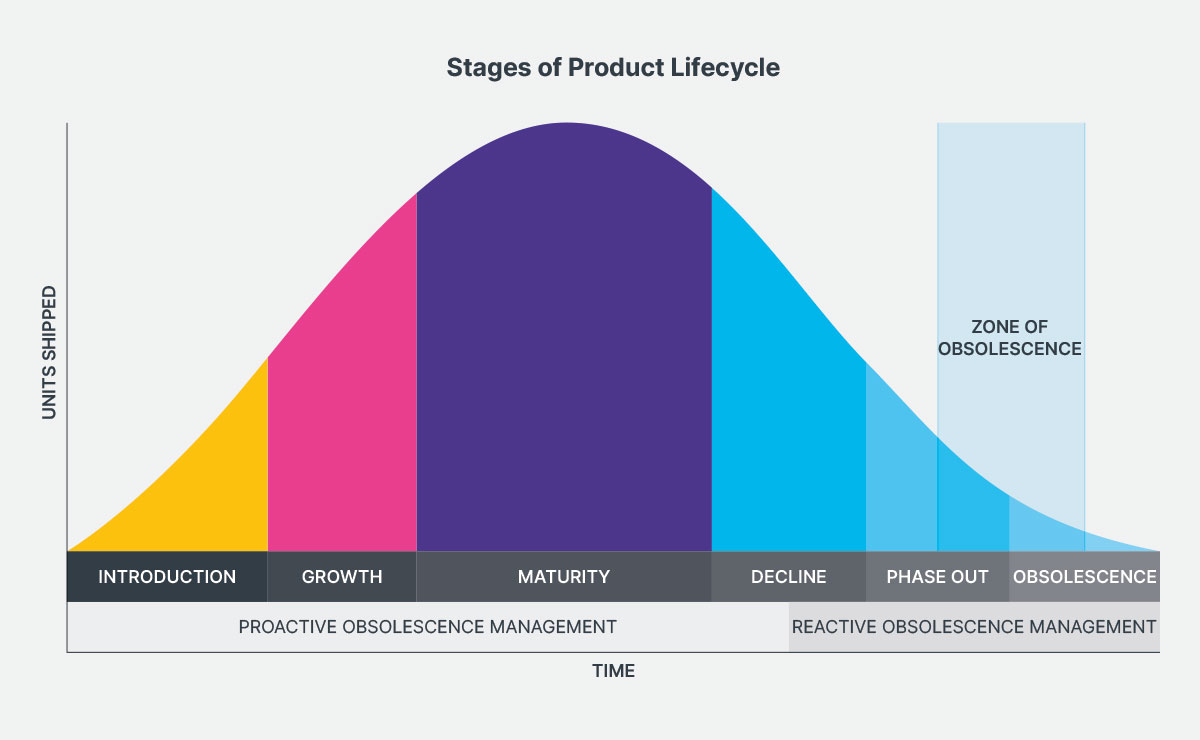

The speed of technology replacement is perpetually accelerating in this ever-changing world, and technology rapidly outdates itself. Moore's law stipulates that processing capability doubles every two years, resulting in numerous current components swiftly falling short as consumer demand for newer end-products shorten component life cycles. The increasing speed of change in the electronics sector means it's unlikely you'll be able to cover every eventuality.

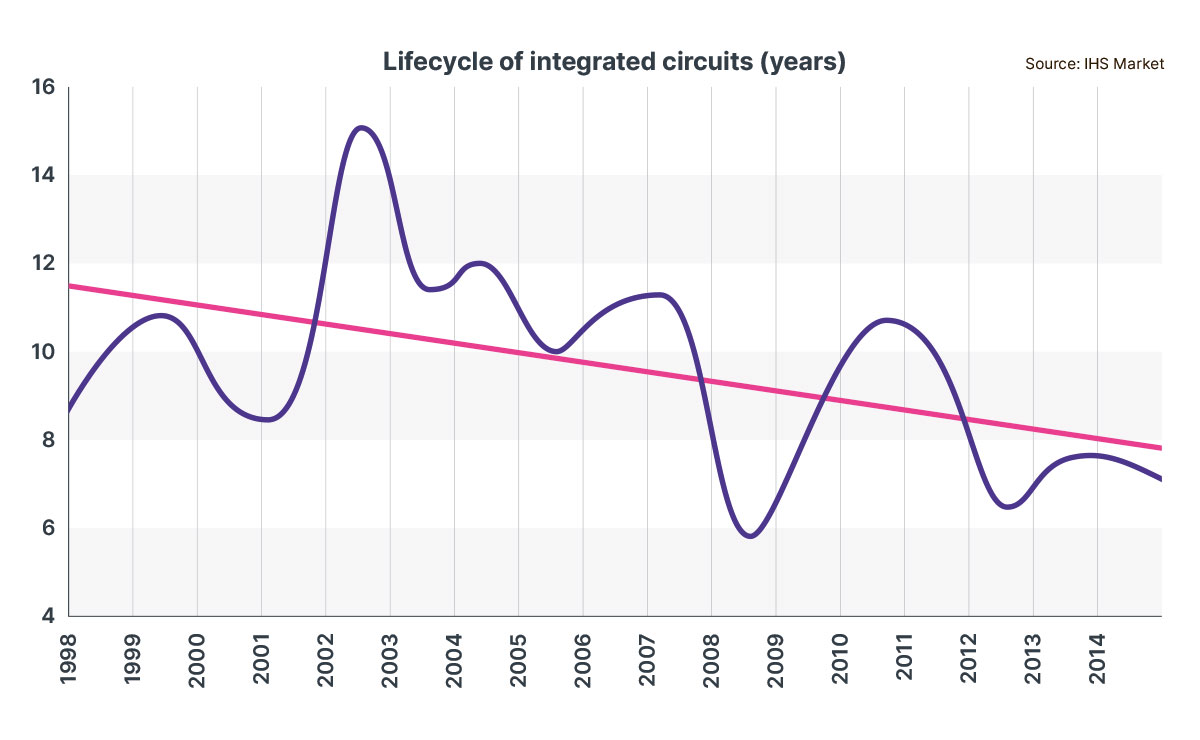

According to a report from IHS Market, component manufacturers per day issue 15 end-of-life (EOL) and 38 product change notifications (PCN). A comparison of the past two decades shows the average life cycle for integrated circuits (IC) has decreased by about 30% on average.

What is the consequence of electronic component obsolescence?

Electronic component obsolescence typically causes disruptions in the supply chain and a knock-on effect is shortages of essential products. Resulting in longer lead times on replacement parts and higher prices for substitute components. Losing a key component at the wrong time can have critical consequences to manufacturing, causing production delays and disruptions, as well as margin squeeze. In extreme cases, an entire product line might need to be redesigned which is a time-consuming and expensive process. Component obsolescence affects almost all segments of electronic manufacturing, including those operating in the high-reliability verticals of military, aerospace, and medical. These days, no segment of the electronics industry can afford to overlook the importance of managing electronic component obsolescence on its business.

Whistler Technology helps you source electronic components which are rarer and harder to find. We are highly experienced, have an extensive network, and can source components globally. We can find exactly what you need, when you need it, keeping your supply chain moving and helping prevent production bottlenecks.